Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

Stainless Steel

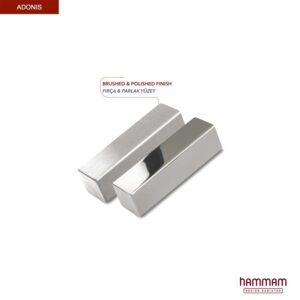

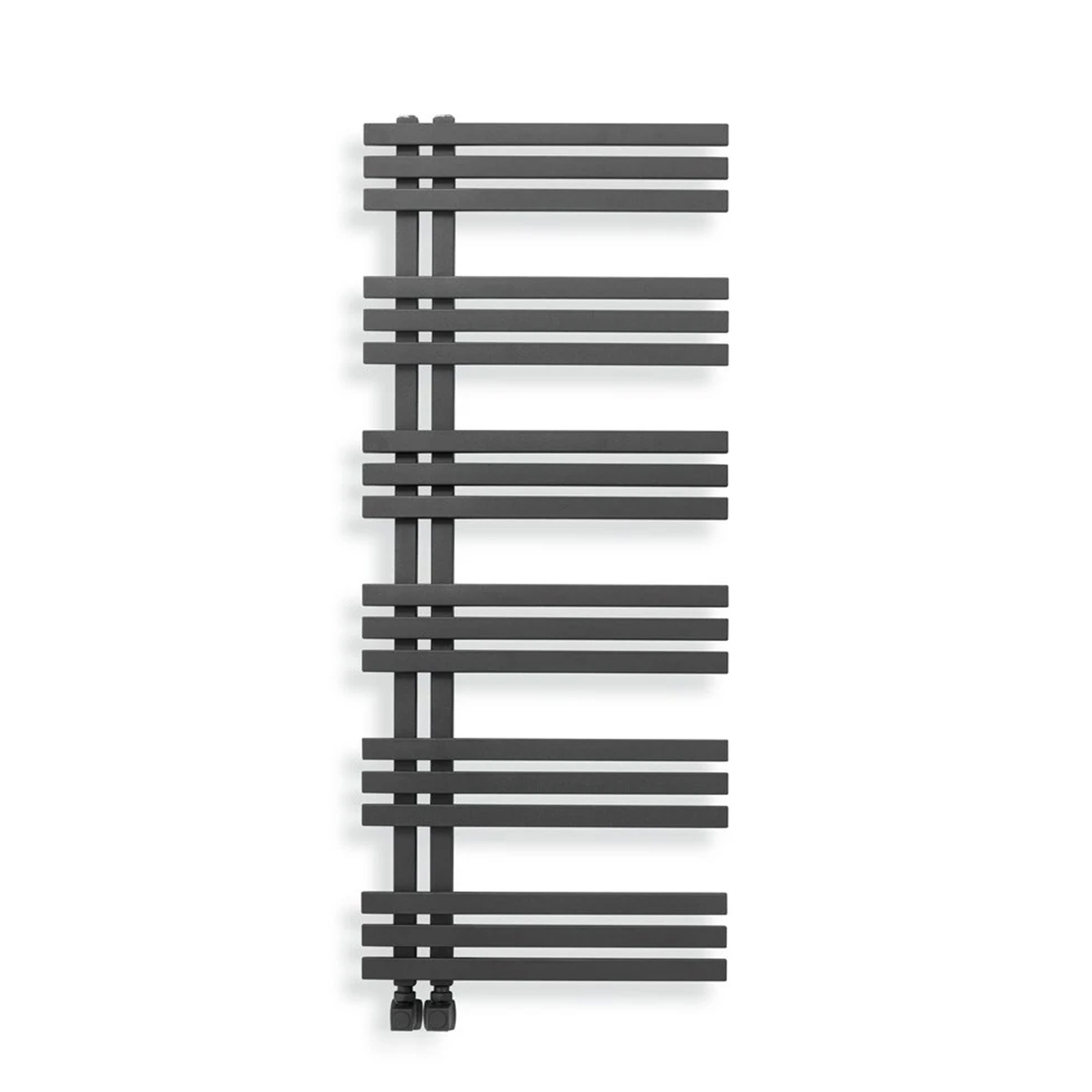

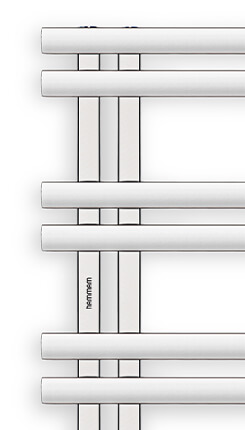

Production of stainless steel towel warmers requires a long term experience. Although many operations are processed with custom made machines, still some operations need excellent hand skills of welding, polishing, buffing at some parts of special design products. We have more than 20 years of experience in production of stainless steel towel warmers. We do not use any filler material during the welding operations, instead we use the technique of melting two stainless steel parts (collectors and tubes) to combine them. This production method requires very well experienced, skilled workforce while providing no- leak warranty on the stainless steel towel warmers. Steel towel warmers are coated (or painted) to cut the reaction of oxygen with the steel material. If this reaction is not prevented, corrosion occurs on steel towel warmers due to the nature of steel. In contrast to steel towel warmers, stainless steel towel warmers do not necessarily require coating or painting on the surface. There is ‘’passive film’’ layer on the stainless steel, which prevents reacting with oxygen. We use custom made polishing machines to obtain polished surfaces. We also make hand polishing on some special designs so our customers can enjoy a perfect mirror surface on exceptional stainless steel design towel warmers.